PRODUCTS

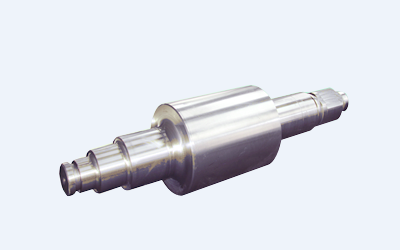

High-speed steel rolls

High-speed steel rolls

Description:

Double poured high speed steel is produced by the vertical spin casting process. The roll is heat treated at high temperatures to obtain optimum material properties, favorable stress levels and homogeneous hardness. The roll have excellent wear resistance in combination with good operation safety,good fire crack resistance and excellent oxidation behavior at high temperatures, and constant material properties throughout the usable shell.

Physical properties & Application:

|

Material code |

Barrel hardness(HSD) |

Neck hardness (HSD) |

Tensile strength (Mpa) |

Application |

|

HCrS |

70-85 |

35-45 |

≥450 |

Hot-rolled plates with rough roll, vertical roll bar line coarse, finishing work rolls |

|

SHSS |

75-85 |

35-45 |

≥450 |

Hot-rolled plates with rough roll, vertical roll bar line coarse, finishing work rolls |

|

HSS I |

70-85 |

35-45 |

≥450 |

|

|

HSS II |

70-95 |

35-45 |

≥450 |

Hot-rolled sheet, strip finishing rolls, bar lines, finishing, pre-finishing work rolls |

|

HSS III |

70-95 |

35-45 |

≥450 |

Chemical analysis:

|

Material code |

C |

Si |

Mn |

Ni |

Cr |

Mo |

V,Nb,W |

|

HCrS |

0.80-1.80 |

0.40-1.00 |

0.50-1.00 |

8.00-15.00 |

0.50-1.50 |

1.50-4.50 |

0.20-0.40 |

|

SHSS |

0.60-1.20 |

0.80-1.50 |

0.50-1.00 |

0.20-1.20 |

3.00-9.00 |

2.50-5.00 |

0.50-2.00 |

|

HSS I |

2.50-3.00 |

0.30-1.00 |

0.50-1.20 |

0.70-1.70 |

15.00-18.00 |

0.70-1.50 |

B0.5-3.0 |

|

HSS II |

1.50-2.00 |

0.30-1.00 |

0.40-1.00 |

0.50-1.50 |

3.00-8.00 |

2.00-8.00 |

V3.0-8.0 |

|

HSS III |

1.50-2.00 |

0.30-1.00 |

0.40-1.00 |

0.50-1.50 |

3.00-8.00 |

2.00-8.00 |

V+Nb3-8 |